SolidSail 1500, it’s 1,000t of fuel reduction per rig per year.

High performance and related commitments

At Chantiers de l’Atlantique we believe that sails can be used as an auxiliary or main propulsion system even for large vessels, without the need to add an extra crew member.

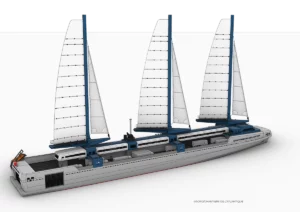

In recognition of this, rigs are designed to accommodate very large sail areas like those of SolidSail 1500 or SolidSail 800.

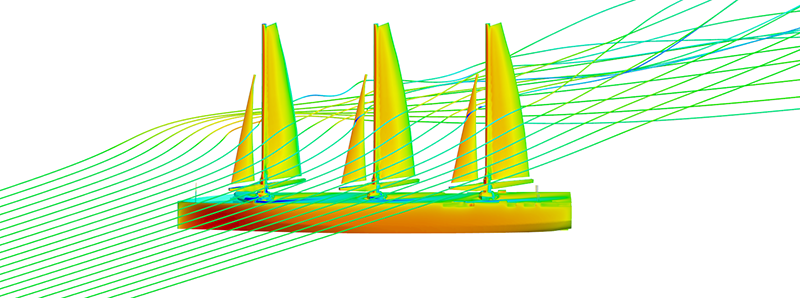

In addition to the requirement for large sail areas, interactions also play an important role in performance; having high sails with a limited number of rigs will cut your risk of losing too much power due to interactions with ship infrastructures or between the sails themselves.

As a major industrial player, we will not just make promises: we can also commit to high performance levels.

SolidSail range of products

From single sails to full rigs

Large ships above 70m require large sail areas

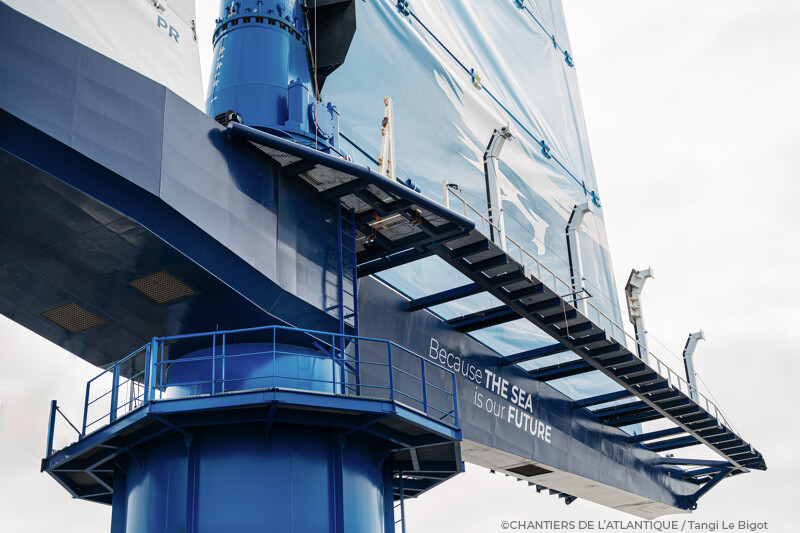

Your crew is not trained to operate sails? We have designed a full rig system that can be remotely operated from the wheelhouse without interfering with regular operations. It can be installed on a new-build program or as part of special refit operations on existing vessels.

Small boats also deserve reliability

Already have a sailing ship using regular sails but don’t want to change them as a regular occurrence?

We have designed SolidSail panels that have a 25-year service life.

SolidSail 800

For 70-150m-long vessels

Simple design

The SolidSail 800 is a full rig, with a main sail and jib mounted on a symmetric boom. It can rotate 360° around its carbon mast while minimising impact on ship integration.

Easy to operate

It is automatically and remotely controlled from the wheelhouse, without the need for crew operation on the rig.

SolidSail 1500

For 120-400m-long vessels

Second-to-none efficiency

SolidSail 1500 is the solution if you want to switch to wind for your main propulsion for vessels measuring about 120m. It has a large surface area for higher propulsion power.

Operation-oriented

Just like the SolidSail 800, ease of operations has been the main design driver since the project kick-off. Due to it’s huge size, a mast tilting capability has been integrated for bridge crossing.

How does it work?

Hoisting and lowering sails

USE IT AS MUCH AS YOU CAN!

Operation is fully automated from the bridge.

Once the order to hoist or lower the sail has been given, the rig will rotate upwind automatically and the sail will be deployed or stored on the main boom.

Full operation lasts up to 7 minutes for hoisting and 5 minutes for lowering.

360° Rotation

SIMPLE AND SAFE BY DESIGN

Endless rig rotation around the mast axis will provide your crew with a safe way to operate their vessel.

Positioning towards the wind can be automatically set up for optimum use of wind-driven propulsion.

A safety feature is also used to make sure the rig never reaches unexpected conditions.

Tilting

Air draft may be limited in some navigation areas.

As SolidSail is high surface/high mast height, it can tilt to reduce its air draft accordingly, with tilting up to 70°.

Choosing SolidSail goes beyond expectations

As an established industrial player, we can offer additional services and commitments for your project.

From simple ideas to industrial commitment

Developing new technologies like SolidSail requires several investments, including time, experience and financial outlay!

2008

First ideas

2008

First Ideas, first table size prototypes: There’s room for wind propulsion technology in commercial vessel applications

2016

J80 prototype

2016

Night J80 sessions to test kinematics of SolidSail folding principles. It’s heavy, but it works!

2017

First cruise vessel concepts

2017

It looks nice but maturity needs to be further increased.

2018-2019

Le Ponant, Main Sail performance tests

2018-2019

Test of Main Sail on Le Ponant cruise vessel. Including cross Atlantic sailing. High sail performance reached.

2018-Now

1/5th scale Rig

2018-Now

Onshore tests of 1/5th scale SolidSail including balestron.

2020-2022

Half scale Rig

2020-2022

Onshore tests of half-scale SolidSail full rig, including automation.

2023-2024

Full scale prototype

2023-2024

Onshore tests of full-scale prototype before its installation on Neoliner vessel.

Solid Sail: the mast

News and testimonials about SolidSail